Box 5 Seepage Meter Operation

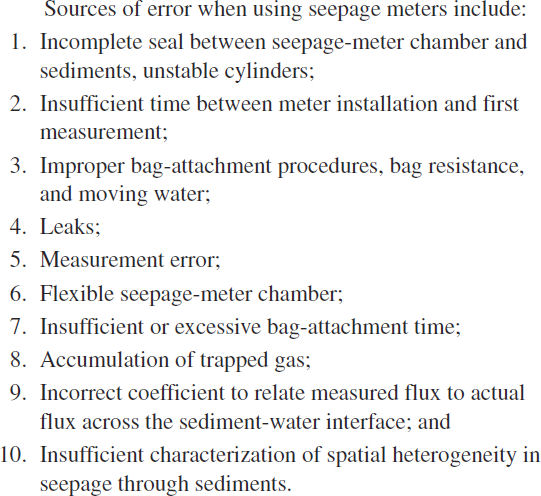

Though seepage meters are useful tools, careful attention must be paid to operational details including meter design, materials, sizing of tubing and bag composition. Applications sometimes require modifications of either the procedure or the meter itself. Rosenberry and others (2008, 2020) present a list of factors affecting meter data sets as shown here in Figure Box 5-1. Their work should be reviewed prior to building or installing meters.

In addition to Rosenberry and others (2008) summary of meter operation errors, Zamora (2008) describes experiments testing meter operation and describes the challenges of using seepage meters in a river setting. Rosenberry and Menheer (2006) developed a system for calibrating seepage meters. Rosenberry and others (2020) present an extensive table of best seepage meter installation and operations practices that should be reviewed before designing and operating meters in field settings.

Meter design includes the components shown in Figure 66. Metal and plastic materials are commonly used if they can be pushed into the bottom sediments to a sufficient depth so that the sides are buried and sealed without disturbing the sediments. Depending on the type of bottom sediments and difficulty or ease of “seating” the meter, the meter diameter and wall thickness design may need modification. When installing and seating the meter the sides may extend into the bottom a few centimeters to 10+ centimeters. The key is to prevent leakage around the meter walls. In all cases, an unobstructed water-filled space between the meter top and sediment interface is required. Meters are typically installed with a slight tilt so that any gasses collected during meter installation or operation will flow out of the meter. In shallow installations, a vent can be used to prevent gas build-up after installation (Figure 66).

Meter installation may disturb the flux conditions at a site. Once a meter is installed, multiple measurements may be required to assure that equilibrium conditions have been reestablished. Without prior knowledge of flux rates, this is accomplished by running the meter and comparing flux rates until some reproducibility of rates is established. The time interval between installation and equilibrium will depend on the site flux rates. Higher rates require shorter times (hours), while lower rates require longer times (days).

Seepage meters were originally designed for shallow lake and wetland studies, and studies of small streams and irrigation ditches with low flow velocities (Lee, 1977). When meters are used to characterize exchange in river systems with rapid streamflow, additional considerations are needed. Both Zamora (2008) and Rosenberry and others (2020) summarize the relevant literature. When the meter protrudes above the stream bed, it redirects stream water and, in some cases, stream water will flow under the meter sides and enter the meter. This generates false over-estimates of seepage (e.g., Zamora, 2008). Flux rates have also been reported to be impacted by the hydraulics of water flowing over and around the collection bag. Investigators have suggested installing shields to limit hydraulic effects (e.g., Libelo and MacIntyre, 1994; Murdoch and Kelly, 2003; Zamora, 2008; Kennedy et al., 2010) as shown in Figure 66. In some settings, it may be possible to extend the meter tubing and bag set up to a submerged nearby location out of the main current (e.g., near the bank or some other more protected zone). Care must be taken to keep the meter and the submerged bag locations at a stream location that has the same stage as the meter, because locating the bag downstream or upstream of a meter changes the gradient conditions controlling seepage (Rosenberry et al., 2020). Both the bag and tubing should remain submerged and secured to the bottom. When meters are installed and left in streams for future measurements, they may become exposed by scour or covered by sediments (Zamora, 2008). Such conditions may require meter removal and reinstallation. If meter installation is planned in stream systems, the seepage meter literature should be carefully reviewed (e.g., Rosenberry et al., 2008; Zamora, 2008; Rosenberry et al., 2020).

Russoniello and Michael (2015) report meter operation in large lakes and along coastlines can be compromised during periods of wave activity. In flume studies, they found small anomalous readings may occur when ratios of wavelength to water depth is less than five. When meters are deployed in these settings, the literature should be consulted to assure proper methods are used (Duque et al, 2020).

In all meters, the diameter and properties of the ports, tubing, valves and bags must not restrict or alter natural flux rates. Meter port opening, tubing, and valve designs must be of a sufficiently large diameter so that no resistance to flow from the meter to the bag occurs (e.g., Zamora, 2008; Rosenberry et al., 2020).

Over time, several modifications to the original bag design have been suggested. Generally, a light-weight, clear, plastic bag is used. It has been found that bags need to be prefilled with water then deflated to remove air prior to meter operation. Shaw and Prepas (1989) found that when a fully deflated (empty) bag is installed and the valve is opened, it expands slightly, drawing a volume of water into the bag that is not related to the natural seepage (referred to as bag memory). Moreover, deflated bags that are stiff (thick walled) resist filling, causing underestimation of seepage rates. Measurements starting with unfilled bags and connected tubes were found to cause inconsistent measurements (e.g., Shaw and Prepas, 1990a,b; Belanger and Montgomery, 1992; Murdoch and Kelly, 2003; Landon et al., 2001; Zamora, 2008; Rosenberry et al., 2020). Generally, depending on the bag size, bags are prefilled with water, 100 to 1000 ml, and the air squeezed out. Harvey and Lee (2000) reported bags should not be overfilled and kinks should be avoided. Isirho and Meyer (1999) examined how meter size and bag type impacted measurements in the laboratory. They concluded bag type had minimal effects on seepage rates. However, Zamora (2008) conducted a series of laboratory experiments and reported seepage values were more repeatable when connected tubes were full of water before opening valves, bags were prefilled with a volume of water and bags were thin walled (0.04 mm).